Butterfly Valve Advantages & Disadvantages

secureluokai

secureluokai

May 25, 2017

May 25, 2017

A butterfly valve belongs to a family of valve known as quarter-turn valves. It functions by completely opening or shutting down itself as the disc rotates a quarter turn. Essentially, it is used to regulate fluid passing through a pipe section.

Butterfly valves design is made in such a way so as to provide total flow with certain control efficiency. Positive shut-off cannot be achieved with butterfly valves. However, the recent usage of latest polymers and increased temperature ratings has made it possible to develop butterfly valves with bubble-tight closure.

Working principle of butterfly valve

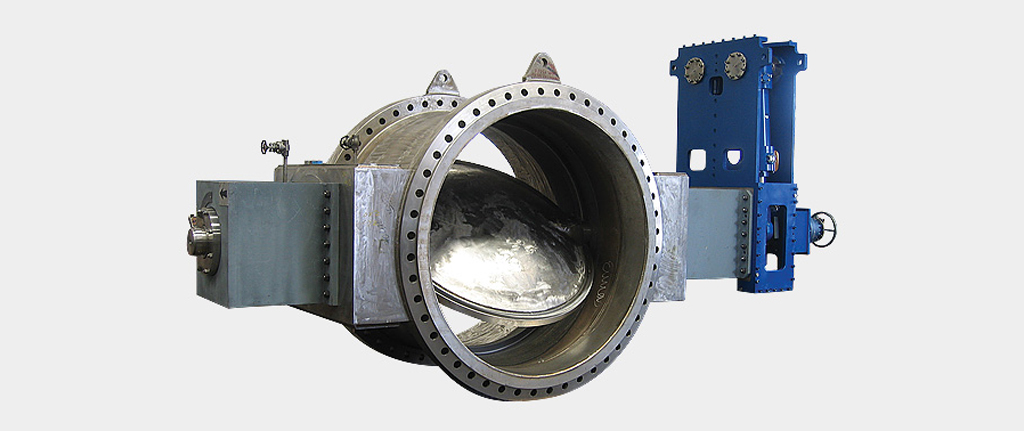

The butterfly valve working principle revolves around a flat, round plate that is placed in the middle of the pipe. A rod is passed through the plate which is linked to an actuator on the exterior of the valve. The plate gets turned either parallel or at right angles towards the flow when the butterfly valve actuator is rotated. In contrast to a ball valve, the plate is always available inside the flow, which creates a pressure drop in the flow irrespective of the position of the valve.

The butterfly valve constitutes a metal disc clasped on a rod. As the valve is shut, the disc is rotated so as to totally block the passageway. When the valve is totally open, the disc is quarter turned to provide an unrestricted flow of the fluid. To shut down or start a butterfly valve, the actuator is given a one-quarter turn to revolve the disk from 0A degree to 90A degree. The actuators applied on butterfly valves differ on the grounds of size and use of the valve. Various types of butterfly valves are present and each one of them is suitable for handling a range of pressure and applications. The resilient butterfly valve that is based on the elasticity of rubber contains the lowest pressure rating. Likewise, the high-performance ones are used in high-pressure systems.

Components of a butterfly valve

Various components of butterfly valve include an outer case or body, a butterfly disk, stem, a rugged positioning plate, packing plus an actuator. The packing ensures a strong seal that surrounds the stem and gives it extra protection in an event when the seal created by the seat gets damaged.

The metal disc or the butterfly is a vital component and is perched on a rod, which stops the passage of liquid when the valve is closed. Essentially, the disc movement depends on the opening or closing of the valve. Further, if the valve is totally open and there is 90 degrees rotation of the disc, in that case, a greater quantity of air or fluid will flow through.

Another component, the resilient seat is fixed on the body to give a proper seal. An additional seal is also provided by the packing in the event of any damage caused to the resilient seat. Butterfly valve has a circular body along with a rotary movement disk closure member, pivotally held by its stem.

Types of Butterfly valve

Butterfly valves offer important benefits over different valves in terms of weight, space, and expenses for huge valve applications. They can be classified into pneumatic, electric and manual butterfly valves.

The major butterfly valve types available in the market include:

- Thermoplastic butterfly valves

These valves come in wafer or lug styles and require different installation procedures. However, the wafer style is more common. The lug style butterfly valves are used in applications which have a low-pressure rating for most of the time.

- Triple offset butterfly valves

These valves are high performing valves. They are used in refineries and in off-shore systems where extreme conditions are prevalent. Many triple offsets use a metal on the metal seat as well as disc closure. It is fire resistant and is rated till 600#class.

- High-performance double offset butterfly valves

This butterfly valve is best suited for managing higher temperature up to 1200 degree F and higher pressure applications. It has double offset disc and stem that makes the disc to “cam” into position while closed. A ‘cam’ is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice versa.

- Inflatable seated butterfly valves

This type of butterfly valve uses an inflatable seat to form a seal that surrounds the disk. The bladder is pumped up pneumatically after the disk reaches the closed point. In such valves, because the seal is formed after the closure of the disc, therefore, less torque is needed to propel the disc to close.

Advantages and disadvantages of butterfly valves

Theadvantages of butterfly valves include:

-

- An in-built simple and affordable design that comprises of lesser parts which make it maintenance friendly and convenient to repair.

- Its wafer-form lightweight body makes it budget-friendly as far as the initial price of the valve and installation cost with regard to in-person hours and piping need is concerned.

- It can transfer mud, with a negligible fluid deposit in the pipeline outlet.

- They achieve good sealing at low pressure and open and shut easily.

- Its disc is light-weight when compared to a ball.

- Butterfly valve needs a much less structural assistance than a ball valve of same diameter needs.

In addition to advantages, there are slight disadvantages of butterfly valves like:

- A certain part of the disc always faces the flow, even when completely opened. The operation of a butterfly valve thus always leads to a pressure switch over the valve irrespective of the setting.

- It has a poor sealing function.

- Throttling by employing butterfly valves is restricted to low-pressure drop systems.

- Possible cavitation and choked flow is a worry when butterfly valves perform.

Applications of butterfly valves

Butterfly valves are widely used in automobile systems. For example, you can detect the butterfly valve in the car carburetor. Accordingly, the valve is used here to regulate the air flow towards the car’s engine. It can open and shut partially to control the amount of air flow through.

The application of butterfly valves in firefighting pipes and tubes is best known due to their easy throttling facilities and adequate pressure limits. These valves are also employed in corrosive and abrasive services. They are also used in high-pressure water and steam facilities that require high temperature. Besides, vacuum service, cooling and circulating water systems also need butterfly valves.

Besides, some of their types like Triple Offset are used in oil, gas, petrochemical, power, chemical and marine industries. Valves can also be used for on-off system or modulating service.

The wide popularity of butterfly valves in industrial applications can be half credited to its properties like quarter-turn function, tight shut-off, and the likes. Further, the component materials and latest designs have enhanced its use in industrial fluid systems.

Wrapping Up

Butterfly valves play an important role in pipelines by helping in controlling the water flow. They have the capacity to stop or start any flow of fluid or varying that is throttling the amount of flow. There are some valves that function better in corrosive systems, while others can manage high-pressure fluids. What are your views on this? How do you ensure that your valves are functioning properly? For more information about various valves specifically required for your industrial plants / business, Contact Flowspec and we will be happy to answer your questions and give you all the details you need.