AT Type Pneumatic Actuator Product Information

AT type pneumatic actuator is one type of actuator to open, close or adjust the valve, which is driven by compressed air. It is also called as air operator or air equipment. Normally, AT type pneumatic actuator can be divided into single-acting pneumatic actuator and double-acting pneumatic actuator.

AT pneumatic actuator is one autoamtic unit of actuator and regulating mechanism. The actuator includes diaphragm type, piston type, scotch yoke type and rack-and-pinion type according to structure. The piston type actuator stroke is big, so it is mostly applicable to working condition that needs bigger thrust force. The diaphragm type actuator stroke is small, which can drive the valve stem directly. The scotch yoke type actuator is featured with big stroke, small space, and torque curve is more suitable the valve torque curve, but does not look nice, and it is mostly used with valve with big torque. The rack-and-pinion type actuator is featured with simple structure, reliable action and safe & explosion proof, it is widely applicable to working condition that require high safety specifications, such as power plant, chemical industry, oil refining and etc. AT type pneumatic actuator operated valve is driven by compressed air, and it is the drive device for starting and closing angle stroke valves such as ball valve and butterfly valve. Besides, it is the ideal device for realizing long-distance concentration of pipelines or separately controlling automatic industrial pipeline, when is equipped with solenoid valve, positioner (opening position indicator), echo device, filter, pressure reducing valve, various limit switches and hand operating devices.Flowspec Luokai can manufacture the AT type pneumatic actuator according to the standard of NAMUR, ISO5211 and DIN3337 with aluminum alloy body and stainless steel materials. Welcome to contact us for detailed information and best quotes if you have any questions or inquiries.

1. FEATURES

- Mounting to valve either directly or via bracket

- Conforming to European and International Standard EN ISO 5211, preferred dimensions

- Double rack & pinion design

- Double acting or Spring return models utilize the same compact body design

- Aluminum body, hard anodized externally and internally, for corrosion and wear resistance

- Adjustable travel stops

- Safe end cover bolting requiring no special tools.

- Anti blow-out drive pinion.

- Namur air connection can be easily mounted with solenoid valve.

- Parallel and diagonal, double square(star) drive.

- Travel adjustment (at each end) ±5°.

- Easy field conversion between double acting and single acting models.

3. STANDARDS

- Medium used: clean, dry and non-corrosive compressed air

- Working pressure of air source: 2.5 bar (36psi) to 8 bar (116psi)

- Temperature of working environment: standard: -20 ~+80 deg C

- High temperature type: -20 ~+180 deg C (the temperature can reach 200 in short time)

- Rotary angle: 90° ± 5°

- Electromagnetic valve power supply: AC220V/DC24V, or according to customers’ needs

- Model: AT series

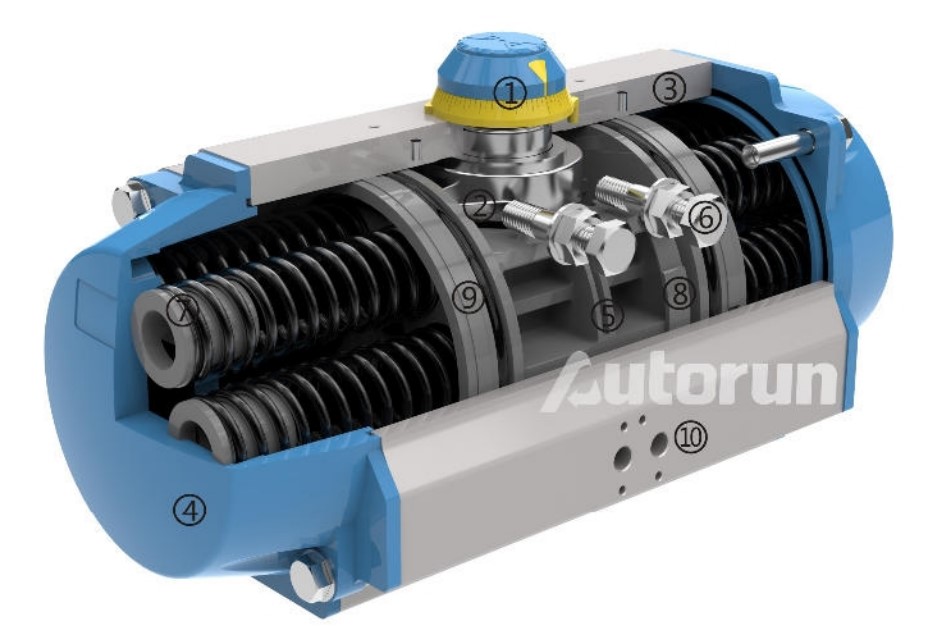

2. WORKING PRINCIPLE

- When the compressed air enters the pneumatic actuator r through Nozzle A, the air will drive the double piston straightly move towards both ends of the cylinder and the piston rack will drive the gear of the rotary shaft by 90 degrees counterclockwise. In this case, the valve will be opened; the air in both ends of pneumatic actuator is discharged through Nozzle B.

On the contrary, when the compressed air enters both ends of the pneumatic actuator through Nozzle B, the air will drive the double piston to straightly move towards the middle position and the piston rack will drive the gear of the rotary shaft by 90°clockwise. In this case, the valve is closed. At this moment, the air in the middle of the pneumatic actuator is discharged through Nozzle A.

What is aforementioned is the transmission principle. According to customer’s needs, the pneumatic actuator can be equipped with transmission principles contrary to the standard type. In other words, the valve will be opened when the rotary s haft rotates clockwise, while the valve is closed when it rotates counterclockwise.

Single acting (spring return type) pneumatic actuation is implemented along the Nozzle A which is the air inlet, while Nozzle B is the air outlet (a muffler shall l be installed in the Nozzle B).

When Nozzle A inlets air, the valve will be opened, while the valve will be closed by the spring force when the air source is cut off.

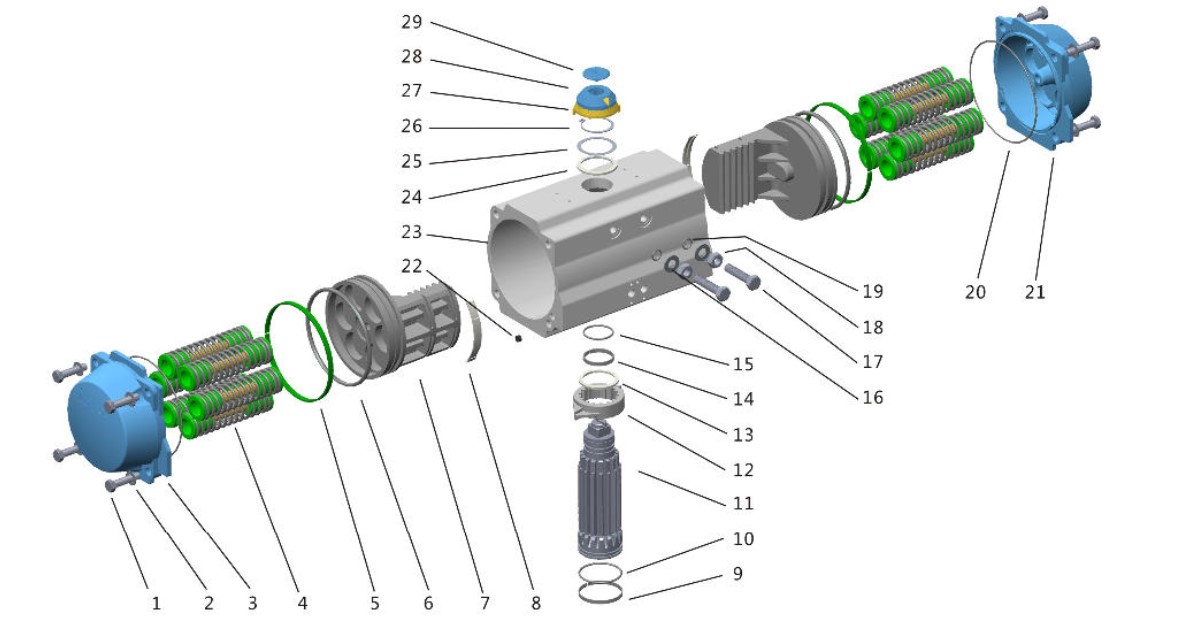

| 序号 N0 | 名称Name | 单台数量 Qty for Each Unit | 标准材料 Standard Material | 可选材料 Materials Selectable |

|---|---|---|---|---|

| 1 | 螺栓 Bolt | 8 | 不锈钢 Stainless Steel | |

| 2 | 螺栓垫片 Bolt Washer | 8 | 不锈钢 Stainless Steel | |

| 3 | 左端盖 Left Cover | 1 | 压铸铝合金 Aluminum Die Casting | 不锈钢Stainless Steel |

| 4 | 弹簧组件 Spring Components | 5-12 | 合金弹簧钢 Alloy Spring Steel | |

| 5 | 活塞环 Piston Ring | 2 | POM | |

| 6 | O型圈(活塞 ) “O” Ring(piston) | 2 | 丁腈橡胶 NBR | |

| 7 | 活塞 Piston | 2 | 压铸铝合金 Aluminum Die Casting | |

| 8 | 导向环 Guide Ring | 2 | Pa66 | |

| 9 | 轴承(轴下) Bearing(output shaft bottom) | 1 | POM | |

| 10 | O型圈(轴下) “O” Ring(output shaft bottom) | 1 | 丁腈橡胶 NBR | 氟橡胶硅橡胶 FPM/Q |

| 11 | 输出轴 Output Shaft | 1 | 碳钢 Carbon Steel | 不锈钢 Stainless Steel |

| 12 | 凸轮 Cam | 1 | 不锈钢 Stainless Steel | |

| 13 | 垫片 Gasket | 1 | POM | |

| 14 | 轴承(轴上) Bearing(at the top of the shaft) | 1 | POM | |

| 15 | O型圈(轴上) “O”Ring(at the top of the shaft) | 1 | 丁腈橡胶NBR | 氟橡胶硅橡胶FPM/Q |

| 16 | 螺母 Nut | 2 | 不锈钢 Stainless Steel | |

| 17 | 调节螺栓 Adjustment Bolt | 2 | 不锈钢 Stainless Steel | |

| 18 | 垫片 Gasket | 2 | 不锈钢 Stainless Steel | 氟橡胶硅橡胶 FPM/Q |

| 19 | O型圈 (调节螺栓) “O” Ring(adjusting bolt) | 2 | 丁腈橡胶 NBR | 氟橡胶硅橡胶 FPM/Q |

| 20 | O型圈 (端盖) “O”Rring(cover) | 2 | 丁腈橡胶 NBR | 不锈钢 Stainless Steel |

| 21 | 右端盖 Right Cover | 1 | 压铸铝合金 Aluminum Die Casting | 氟橡胶硅橡胶 FPM/Q |

| 22 | 堵头 Plug | 1 | 丁腈橡胶 NBR | 不锈钢 Stainless Steel |

| 23 | 缸体 Block | 1 | 挤压铝合金Aluminum Extrusion | |

| 24 | 垫片 Gasket | 1 | POM | |

| 25 | 垫片 Gasket | 1 | 不锈钢 Stainless Steel | |

| 26 | 轴用挡圈 Shaft Ring | 1 | 不锈钢 Stainless Steel | |

| 27 | 指示器固定架 Indicator Supporting Structure | 1 | ABS | |

| 28 | 指示器主体 Main Body of the Indicator | 1 | ABS | |

| 29 | 螺钉 Bolt | 1 | ABS | |

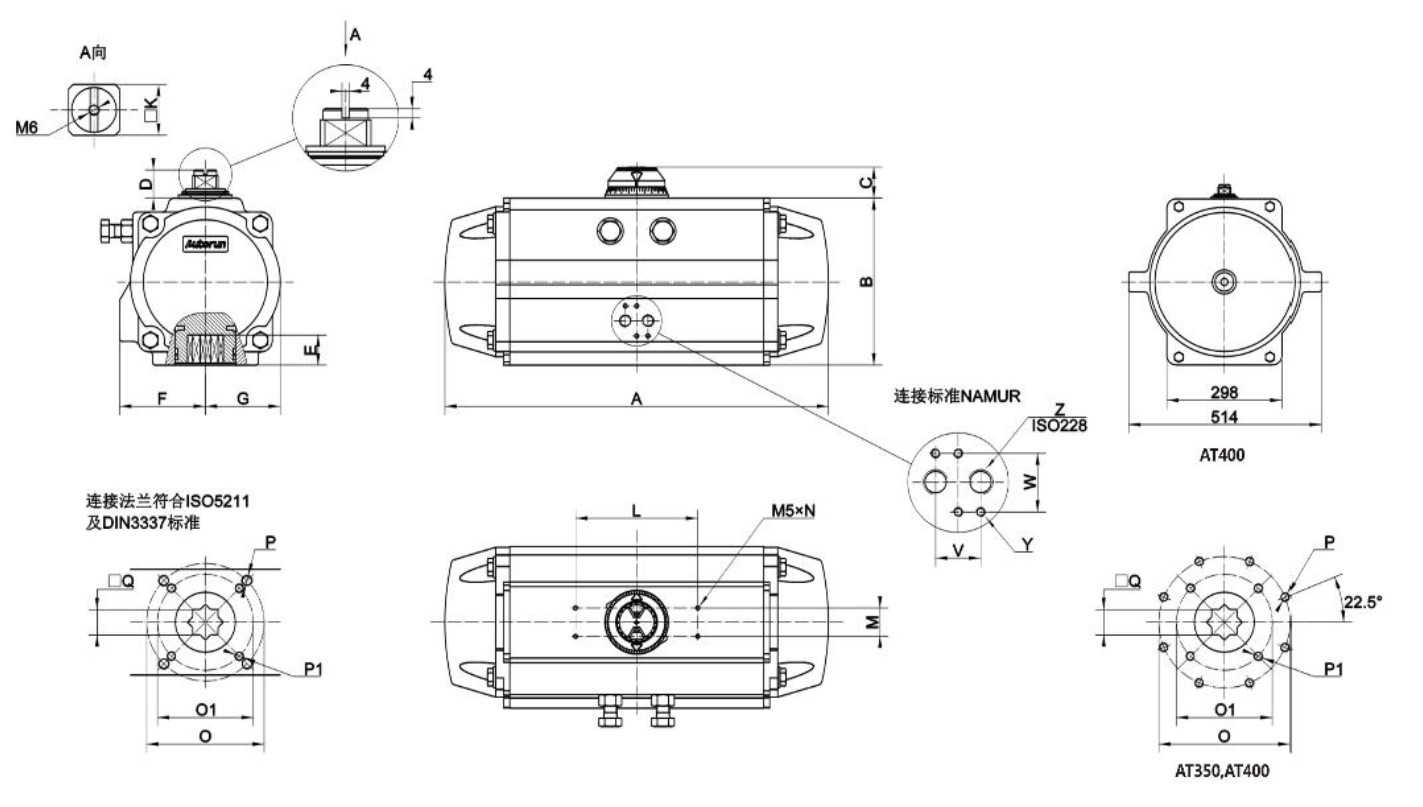

| 型号Model | AT042 | AT050 | AT063 | AT075 | AT088 | AT100 | AT115 | AT125 | AT145 | AT160 | AT190 | AT210 | AT240 | AT270 | AT300 | AT350 | AT400 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ISOflange | F03/F05 | F03/F05 | F03/F05 | F05/F07 | F05/F07 | F07/F10 | F07/F10 | F07/F10 | F10/F12 | F10/F12 | F12/F14 | F12/F14 | F16 | F16 | F16 | F16/F25 | F16/F25 |

| A | 122 | 143 | 162 | 212 | 248 | 270 | 318 | 345 | 408 | 440 | 530 | 592 | 670 | 723 | 870 | 935 | 1035 |

| B | 55 | 68 | 84 | 100 | 115 | 126 | 145 | 157 | 178 | 196 | 233 | 255 | 292 | 332 | 355 | 410 | 466 |

| C | 20 | 20 | 20 | 23 | 23 | 23 | 23 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 |

| D | 18 | 18 | 19 | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 25 | 25 | 25 | 25 | 25 |

| E | 12 | 12 | 16 | 16 | 19 | 19 | 24 | 24 | 29 | 29 | 38 | 38 | 48 | 48 | 48 | 48 | 48 |

| F | 33 | 40.5 | 46 | 52 | 56 | 67 | 78 | 80 | 91 | 100 | 112 | 121 | 130 | 147 | 173 | 195 | 260 |

| G | 24 | 29 | 36 | 41.5 | 49 | 56 | 64 | 71 | 80 | 88 | 105 | 116 | 130 | 147 | 161 | 190 | 260 |

| K | 10 | 11 | 11 | 17 | 17 | 17 | 17 | 27 | 27 | 27 | 27 | 27 | 36 | 36 | 36 | 36 | 36 |

| L | 50 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 |

| M | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| N | 4-M5×9 | 4-M5x9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 |

| 。 | 50 | 50 | 50 | 70 | 70 | 102 | 102 | 102 | 125 | 140 | 140 | 140 | 165 | 165 | 165 | 254 | 254 |

| P | 4-M6×9 | 4-M6x9 | 4-M6x9 | 4-M8×12 | 4-M8×12 | 4-M10×15 | 4-M10×15 | 4-M10×15 | 4-M12×18 | 4-M16×24 | 4-M16×24 | 4-M16×24 | 4-M20×30 | 4-M20×30 | 4-M20×30 | 8-M16×24 | 8-M16×24 |

| O1 | 36 | 36 | 36 | 50 | 50 | 70 | 70 | 70 | 102 | 102 | 125 | 125 | — | — | — | 165 | 165 |

| P1 | 4-M5x8 | 4-M5x8 | 4-M5x8 | 4-M6×9 | 4-M6×9 | 4-M8×12 | 4-M8×12 | 4-M8×12 | 4-M10×15 | 4-M10×15 | 4-M12×18 | 4M12×18 | — | — | — | 4-M20×30 | 4-M20×30 |

| Q | 9 | 11 | 14 | 14 | 17 | 17 | 22 | 22 | 27 | 27 | 36 | 36 | 46 | 46 | 46 | 46 | 46 |

| V | 20 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 40 | 40 | 40 | 40 |

| w | 29 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 45 | 45 | 45 | 45 |

| Y | 4-M4×9 | 4-M5x9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M5×9 | 4-M6x10 | 4-M6×10 | 4-M6×10 | 4-M6×10 |

| z | G1/8″ | G1/8″ | G1/8″ | G1/8″ | G1/8″ | G1/4″ | G1/4″ | G1/4″ | G1/4″ | G1/4″ | G1/4° | G1/4″ | G1/4″ | G3/8″ | G1/2° | G1/2″ | G1/2″ |

| 执行器型号 Actuator Model |

2.5bar | 3.0bar | 3.5bar | 4.0bar | 4.5bar | 5.0bar | 5.5bar | 6.0bar | 7.0bar | 8.0bar |

|---|---|---|---|---|---|---|---|---|---|---|

| AT042D | 3.6 | 4.3 | 5 | 5.7 | 6.4 | 7.3 | 8 | 8.7 | 10 | 11.6 |

| AT050D | 8.3 | 10.0 | 11.6 | 13.3 | 15.0 | 16.6 | 18.3 | 19.9 | 23.3 | 26.6 |

| AT063D | 14.7 | 17.6 | 20.5 | 23.5 | 26.4 | 29.3 | 32.2 | 35.2 | 41.0 | 46.9 |

| AT075D | 29.1 | 34.9 | 40.7 | 46.5 | 52.3 | 58.2 | 64.0 | 69.8 | 81.4 | 93.0 |

| AT088D | 45.7 | 54.9 | 64.0 | 73.2 | 82.3 | 91.5 | 101 | 110 | 128 | 146 |

| AT100D | 66.5 | 79.7 | 93.0 | 106 | 120 | 133 | 146 | 160 | 186 | 213 |

| AT115D | 107 | 129 | 150 | 172 | 193 | 215 | 236 | 258 | 301 | 344 |

| AT125D | 138 | 166 | 194 | 221 | 249 | 277 | 304 | 332 | 387 | 443 |

| AT145D | 217 | 261 | 304 | 348 | 391 | 434 | 478 | 521 | 608 | 695 |

| AT160D | 283 | 340 | 397 | 453 | 510 | 567 | 623 | 680 | 793 | 907 |

| AT190D | 538 | 646 | 753 | 861 | 969 | 107 | 1185 | 1292 | 1508 | 1723 |

| AT210D | 658 | 789 | 920 | 1052 | 1184 | 1316 | 1447 | 1579 | 1842 | 2105 |

| AT240D | 966 | 1160 | 1352 | 1546 | 1740 | 1933 | 2126 | 2320 | 2706 | 3093 |

| AT270D | 1468 | 1761 | 2055 | 2349 | 2642 | 2936 | 3229 | 3523 | 4110 | 4697 |

| AT300D | 1908 | 2289 | 2670 | 3052 | 3434 | 3815 | 4197 | 4578 | 5341 | 6104 |

| AT350D | 2856 | 3427 | 3998 | 4570 | 5141 | 5712 | 6283 | 6854 | 7997 | 9139 |

| AT400D | 4069 | 4883 | 5697 | 6511 | 7325 | 8139 | 8953 | 9767 | 11394 | 13022 |

| 执行器 型号 Actuator Model |

弹簧 数量 Spring Quantity |

空气压力扭矩Air Pressure Torque | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.5Bar | 5.0Bar | 5.5Bar | 6.0Bar | 7.0Bar | 8.0Bar | 弹簧复位扭矩 Spring Return Torque |

|||||||||

| 0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

0° 开始 Start |

90° 结束 End |

||

| AT050S | 10 | 8.2 | 5.2 | 9.8 | 6.9 | 11.5 | 8.5 | 13.2 | 10.2 | 16.5 | 13.5 | 19.8 | 16.8 | 9.7 | 6.8 |

| AT063S | 10 | 15.3 | 9.4 | 18.2 | 12.4 | 21.1 | 15.3 | 24.1 | 18.2 | 29.9 | 24.1 | 35.8 | 29.9 | 16.9 | 11.1 |

| AT075S | 10 | 30.2 | 17.7 | 36 | 23.5 | 41.8 | 29.3 | 47.6 | 35.1 | 59.2 | 46.7 | 70.9 | 58.4 | 34.6 | 22.1 |

| AT088S | 10 | 45.6 | 24.5 | 54.7 | 33.7 | 63.9 | 42.8 | 73 | 52 | 91.3 | 70.2 | 110 | 88.5 | 57.8 | 36.7 |

| AT100S | 10 | 68.9 | 40.7 | 82.2 | 54 | 95.5 | 67.3 | 109 | 80.5 | 135 | 107 | 162 | 134 | 78.8 | 50.6 |

| AT115S | 10 | 111 | 62.1 | 133 | 83.6 | 154 | 105 | 176 | 127 | 219 | 170 | 261 | 212 | 131 | 82 |

| AT125S | 10 | 144 | 84 | 172 | 112 | 200 | 140 | 227 | 167 | 283 | 223 | 338 | 327 | 165 | 105 |

| AT145S | 10 | 227 | 133 | 270 | 177 | 313 | 220 | 357 | 263 | 444 | 350 | 531 | 437 | 258 | 165 |

| AT160S | 10 | 286 | 178 | 343 | 235 | 399 | 291 | 456 | 348 | 569 | 461 | 683 | 575 | 332 | 224 |

| AT190S | 10 | 440 | 210 | 656 | 426 | 765 | 535 | 871 | 641 | 1087 | 857 | 1302 | 1072 | 586 | 379 |

| AT210S | 10 | 473 | 253 | 737 | 517 | 605 | 657 | 1000 | 780 | 1263 | 1043 | 1526 | 1306 | 719 | 521 |

| AT240S | 10 | 887 | 566 | 1066 | 745 | 1246 | 923 | 1423 | 1102 | 1781 | 1459 | 2138 | 1817 | 1042 | 721 |

| AT270S | 10 | 1472 | 982 | 1758 | 1281 | 2059 | 1567 | 2345 | 1868 | 2932 | 2455 | 3519 | 3042 | 1490 | 1060 |

| AT300S | 10 | 1814 | 1074 | 2193 | 1458 | 2577 | 1837 | 2956 | 2221 | 3719 | 2984 | 4482 | 3747 | 2122 | 1460 |

| AT350S | 10 | 2531 | 1361 | 3105 | 1929 | 3673 | 2503 | 4247 | 3071 | 5390 | 4212 | 6532 | 5356 | 3405 | 2346 |

| AT400S | 10 | 3833 | 3041 | 4640 | 2653 | 5461 | 4669 | 6268 | 4281 | 7895 | 5908 | 9523 | 7526 | 4115 | 2624 |