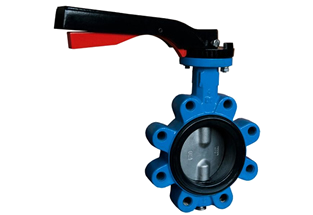

Lug Butterfly Valve Rubber Lined

PN10 / PN16 / CL125LB

2″~24″ (50~600mm)

Cast Iron, Ductile Iron

Lug Butterfly Valve Rubber Lined Product Information

Lug butterfly valve rubber lined is available to do the repair in the downstream pipelines and equipment directly, which is mounted between two matching flanges of the piping with bolts & nuts. According to actual piping conditions, lug type butterfly valve can be manufactured according to different flanges standards, such as ASMEB16.1, EN1092, AS2129, DIN2501, BS4504, JIS10K, GB 17241.6. Lugged type butterfly valve can be mounted onto the piping ends as exhaust valve too. Flowspec Luokai can manufacture the lugged butterfly valve in accordance with the standards of EN593, API609 and ASME B16.34 with the sizes of 2″~24″ (DN50~600mm).

Welcome to contact us for detailed information and best quotes if you have any questions or inquiries.

1. FEATURES

- Simple and compact construction

- Small in size and light in weight

- Quick 90° on-off operation, low torque

- Good sealing capability, no leakage

- It can be mounted wherever needed

- Lugged ends

3. STANDARDS

- Design & manufacturing: ASME B16.34, EN593, API609

- Face to face: ANSI B16.10, EN 558-1, API609

- Matching flanges: ANSI B16.1, EN 1092, JIS10K, AS 2129

- Top flange: ISO 5211

- Inspection & testing: API598, GB13927

2. TECHNICAL SPECIFICATIONS

- PN10 / PN16 / 125LB / 150LB / JIS10K / 150PSI / 200PSI

- Size: 2″~24″ (DN50~600mm)

- Materials: cast iron A126 B (GG25), ductile iron A536 65-45-12 (GGG40), steel A216 WCB, stainless steel 304(CF8), stainless steel 316(CF8M), bronze B148 C954

- Epoxy coating with thickness ≥ 250μm

- Applicable medium: water, sewage, sea water, air, corrosive liquids

- Applicable temperature: -45℃~+150℃ (higher temperature is available upon request)

4. APPLICATIONS

1.Water works, water projects

2.Environment protection

3.Public facilities

4.Power plant

5.Building industry, real estate

6.Petroleum, chemical industry

7.Steel work, metallurgy

8.Paper plant

9.Food & beverage

10.Water treatment plant