200X Pressure Reducing Valve Product Descriptions

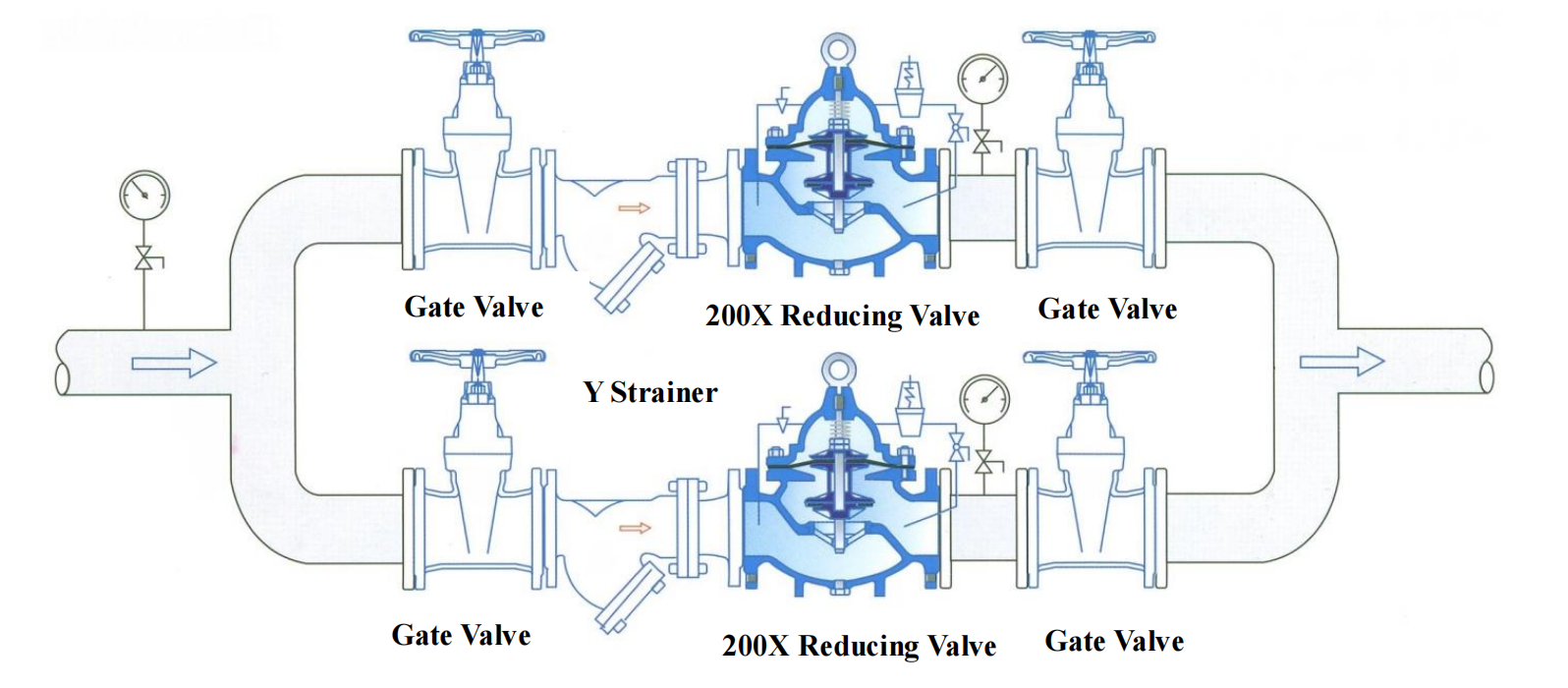

200X pressure reducing valve is one type of automatic control valve to regulate and control pipe pressure through the fluids self-energy. 200X pressure reducing valve is applicable to living water supply, firefighting water supply and industrial water supply system. It can adjust the main valve outlet pressure without change because of affecting the inlet pressure or inlet flow change, but will keep on the set one safely and reliably. The valve can also adjust the set pressure to achieve the purpose of reducing the pressure. 200X diaphragm type pressure reducing valve has accurate pressure reducing, stable, safe and reliable performance, convenient installation & adjustment and long service life. Flowspec Luokai can manufacture the 200X pressure reducing valve applicable to be mounted on the pipeline with sizes ≤ DN600.

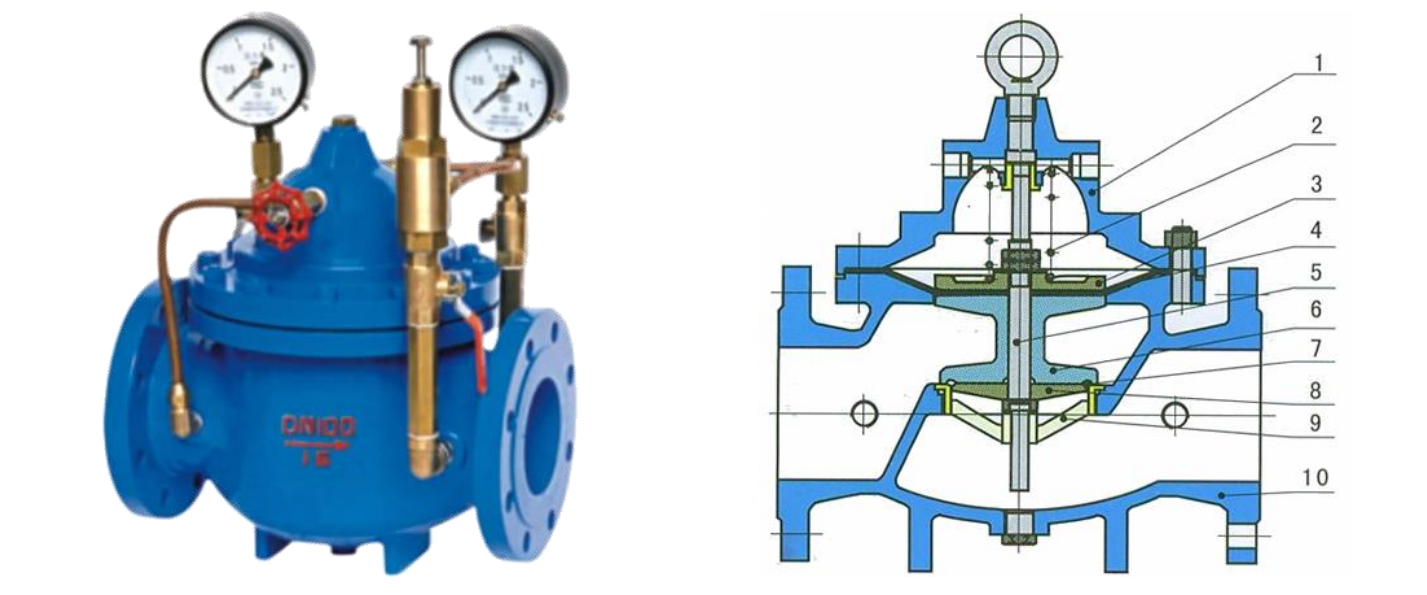

| Item | Part | Material |

|---|---|---|

| 1 | Bonnet | Cast Iron., Ductile Iron, Carbon Steel, Stainless Steel |

| 2 | Spring | Spring Steel, Stainless Steel |

| 3 | Diaphragm Pressure Pad | Cast Iron., Ductile Iron, Carbon Steel, Stainless Steel |

| 4 | Diaphragm | NBR+Nylon,EPDM+Nylon |

| 5 | Stem | A182-F6a, A276 420 |

| 6 | Disc | Cast Iron., Ductile Iron, Carbon Steel, Stainless Steel, Brass |

| 7 | O-ring | NBR, EPDM |

| 8 | O-ring Pressure Pad | Cast Iron., Ductile Iron, Carbon Steel, Stainless Steel |

| 9 | Seat | Copper Alloy, Stainless Steel |

| 10 | Body | Cast Iron., Ductile Iron, Carbon Steel, Stainless Steel |

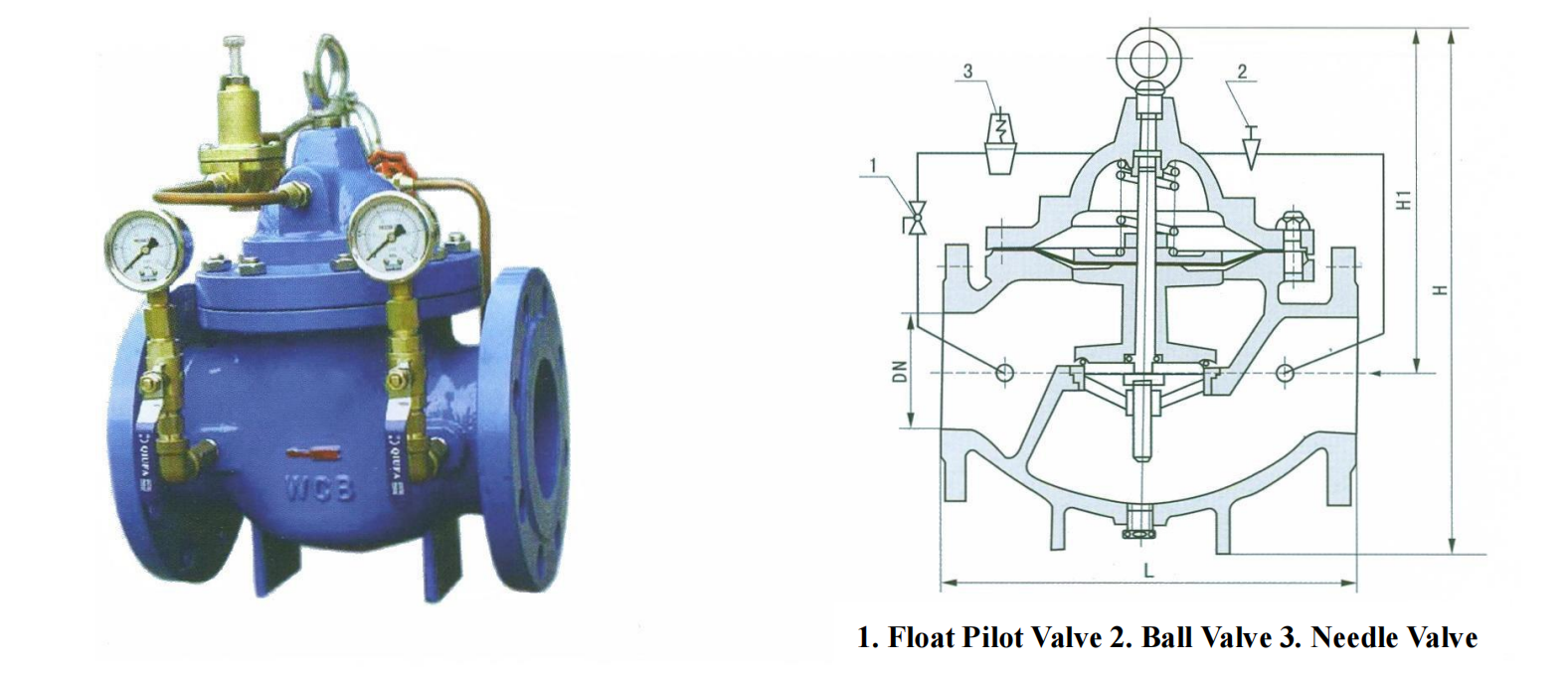

| MAIN CONNECTION DIMENSIONS | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | 150 | 160 | 180 | 200 | 203 | 216 | 241 | 292 | 330 | 356 | 495 | 622 | 698 | 787 | 914 | 978 | ||

| 190 | 200 | 215 | 241 | 270 | 200 | 330 | 400 | 480 | 550 | 622 | 685 | 750 | 811 | 935 | ||||

| 220 | 230 | 300 | 340 | 350 | 400 | 450 | 550 | 640 | 700 | 800 | 840 | 900 | 1100 | |||||

| H1 | 179 | 179 | 179 | 210 | 210 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 696 | 735 | 735 | 778 | 873 |

| H | 342 | 342 | 342 | 395 | 395 | 405 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 910 | 1096 | 1096 |

NOTES:

As we are constant endeavoring to improve the performance of our equipment.

The company reserves the right to make alteration from time to time and equipment differ from that detailed in this brochure.

- Convenient installation and adjustment

- Stable, safe and reliable performance

- Long service life

- Design & manufacturing: Q / FSF-2014

- Face to face: Q / FSL-2014

- Flanged ends: GB/T 17241.6, GB/T 9113, ASME B16.1 / B16.5, EN 1092, AS4087, DIN2532-2534, DIN2542-2544

- Inspection & testing: GB / T 13927, API 598, EN12266

- Quality assurance: ISO 90001

- Applicable medium: water, sewage, sea water

- Applicable temperature: 0 ℃ ~ + 80 ℃ (higher temperature is available upon request)

- Nominal pressure: PN1.0 / PN1.6MPa / PN2.5MPa, ANSI 125 / 150LB,

- Size: 3/4″~ 24″ (DN20 ~ DN600mm)

- Materials: cast iron (GG25, ASTM A126 B), ductile iron (GGG50, GJS500, DIN1693, BS EN1563, ASTM A536 65-45-12), carbon steel (WCB), stainless steel 304 (CF8), stainless steel 316 (CF8M), brass, bronze (C83600, C95800)

- Water projects

- High buildings

- Water treatment industry

- Power plant

- Chemical industry