Features of Eccentric Hemispherical Valve

secureluokai

secureluokai

August 6, 2025

August 6, 2025

(1) Innovative Sealing Design with Excellent Sealing Effect and Long Service Life

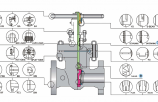

The valve’s sealing pair adopts a spherical structure, inherently providing an excellent sealing foundation. More importantly, the rotation center of the valve disc is designed with a precise eccentricity from the center of the valve seat. This unique structure creates an eccentric cam wedging effect during the valve closing process – as the closing action progresses, the fitting force between the valve disc and the valve seat gradually increases, achieving a “tighter as it closes” sealing effect. Even when the sealing surface is slightly worn due to long-term medium scouring, this structure can still automatically compensate, continuously ensuring the sealing performance.

Benefiting from the cam effect, the valve can also easily achieve bidirectional sealing, greatly improving the flexibility of applicable scenarios. At the same time, when the valve disc is opened or closed, the spherical surface and the valve seat can quickly separate and fit, making the friction between the sealing pairs almost “zero contact”. This not only significantly prolongs the service life of the valve but also effectively reduces the torque required for opening and closing, making the operation more labor-saving and convenient.

(2) Excellent Scour Resistance and Strong Flow Capacity

When the valve is fully open, the valve disc is cleverly “hidden” on the side of the valve cavity. This design greatly reduces the chance of the medium directly scouring the valve disc, thereby effectively improving the valve’s scour resistance and extending its service life under harsh working conditions. Meanwhile, this structural design also increases the cross-sectional area of medium flow, reduces fluid resistance, and significantly enhances the valve’s flow capacity, enabling it to more efficiently meet the flow requirements of various pipeline systems.

(3) Selected Special Materials for Significantly Extended Service Life

The sealing pair of the valve is surfacing welded with special hard alloy and processed and formed through special techniques, making the sealing surface not only have extremely high surface hardness but also excellent conformity with the valve seat. This not only ensures excellent sealing performance but also endows the sealing pair with excellent wear-resistant and scour-resistant properties, fundamentally prolonging the service life of the sealing pair.

For systems with extremely severe wear such as slag flushing, ash unloading, coal injection, and material discharging in metallurgical, building materials, and other industries, the key parts in the valve cavity adopt the process of supersonic spraying of alloy materials. This high-hardness protective coating can effectively resist the strong scouring and wear of the medium, providing a solid protection for the core components of the valve, ensuring that the valve can maintain stable performance and a long service life under extreme working conditions.

(4) Fast Opening and Closing Action, Low Failure Rate, and Convenient Maintenance

The valve adopts a 90-degree angle stroke design, with fast and efficient opening and closing actions, which can quickly respond to the opening and closing requirements of the pipeline system. In terms of driving methods, it can be flexibly equipped with various driving devices such as manual, electric, and pneumatic, meeting the needs of different automation levels and operating scenarios.

In addition, the overall structure of the valve is designed to be simple, reducing complex component connections, thereby reducing the probability of failures. At the same time, the simple structure also makes the maintenance of the valve more convenient. Whether it is daily inspection or component replacement, it can be easily carried out, effectively reducing the maintenance cost and downtime of the equipment.