Composition and Structural Characteristics of Butterfly Valves

secureluokai

secureluokai

December 19, 2025

December 19, 2025

I. Composition of Butterfly Valves

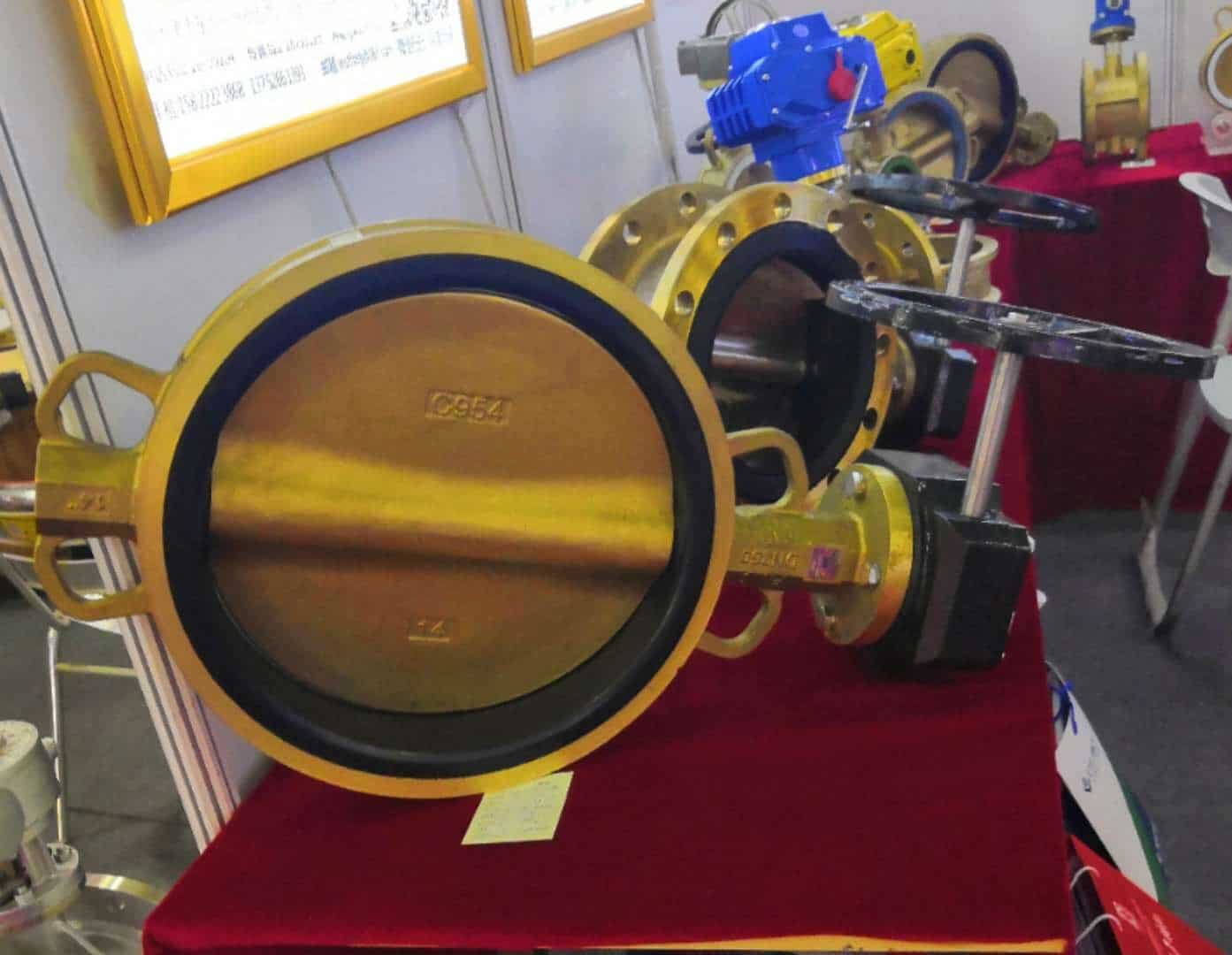

A butterfly valve is a type of compact fluid control valve, whose main structure consists of two major parts: core functional components and auxiliary supporting components.

Core functional components include the valve body, valve disc, valve stem, bearings, sealing device, and operating mechanism.

The valve body serves as the basic load-bearing component of the butterfly valve, providing installation space and a supporting structure for all internal components.

The valve disc is the key element for controlling the on-off state of fluid, which can rotate with the valve stem to achieve opening and closing actions.

The valve stem undertakes the force transmission function, connecting the operating mechanism and the valve disc.

Bearings are used to reduce the friction resistance when the valve stem rotates, ensuring smooth operation.

The sealing device is responsible for isolating the medium inside and outside the valve to avoid leakage problems.

The operating mechanism is the control terminal of the valve, which can drive the valve stem to rotate manually, electrically, pneumatically, or through other means.

II. Structural Characteristics of Butterfly Valves

A butterfly valve is a fluid control device with a unique structure. Its structural design centers on the core requirements of light weight, high efficiency, and quick opening and closing, boasting distinct advantages.

In terms of component composition, the key actuating components of a butterfly valve are concentrated in the valve body, valve disc, valve stem, bearings, sealing device, and operating mechanism. The overall structure is simplified, with fewer parts compared with gate valves and globe valves. This not only reduces manufacturing costs but also facilitates subsequent installation and maintenance.

In terms of operating principle, these core components form a linkage structure with the valve stem as the rotation center through ingenious layout and combination. When the operating mechanism drives the valve stem to rotate, the valve disc can perform a 0°–90° rotary motion inside the valve body. During the rotation, it closely cooperates with the sealing device, which can not only quickly realize the full opening or full closing of the pipeline but also regulate fluid throttling at partial opening degrees. This design ensures that the butterfly valve maintains a smooth and stable operating state during opening and closing without jamming, thereby efficiently achieving precise control of fluid. It is widely used in fluid pipeline systems of various fields such as water supply and drainage, chemical industry, and metallurgy.

If you have any questions or inquiries, please feel free to contact us with sales@lokvalve.com or WhatsApp: +8618616568786