Classification of ball valves by structural form

secureluokai

secureluokai

July 27, 2025

July 27, 2025

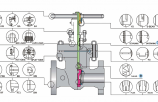

Ball valves can be classified into the following three types by structural form:

Floating ball valve

1.The ball is floating. Under the action of medium pressure, the ball can produce a certain displacement and press tightly on the sealing surface of the outlet end to ensure the sealing of the outlet end. It features a simple structure and good sealing performance. However, the load of the working medium borne by the ball is completely transmitted to the outlet sealing ring, so it is necessary to consider whether the material of the sealing ring can withstand the working load of the ball medium. This structure is widely used in medium and low pressure ball valves.

Fixed ball valve

2.The ball is fixed and does not move under pressure. Fixed ball valves are all equipped with floating valve seats. Under the medium pressure, the valve seat moves to make the sealing ring press tightly on the ball to ensure sealing. Bearings are usually installed on the upper and lower shafts of the ball, resulting in small operating torque, making it suitable for high-pressure and large-diameter valves.

In recent years, oil-sealed ball valves have emerged to reduce the operating torque of ball valves and enhance sealing reliability. By injecting special lubricating oil between the sealing surfaces to form an oil film, they not only improve sealing performance but also reduce operating torque, making them more suitable for high-pressure and large-diameter ball valves.

Elastic ball valve

3.The ball is elastic. Both the ball and the valve seat sealing ring are made of metal materials, with extremely high sealing specific pressure. Since the pressure of the medium itself cannot meet the sealing requirements, external force must be applied. This type of valve is suitable for high-temperature and high-pressure media.

The elastic ball achieves elasticity by an elastic groove opened at the lower end of the inner wall of the ball. When closing the channel, the wedge-shaped head of the valve stem expands the ball to press it against the valve seat for sealing. Before rotating the ball, the wedge-shaped head is loosened, and the ball returns to its original shape, creating a small gap between the ball and the valve seat, which can reduce the friction of the sealing surface and the operating torque.